Rear Camber Modification Write Up + Photo

-

Guest

Guest -

1artworkzSenior Member

1artworkzSenior Member- 1143

I might. I have one other set I have made for one other person300cars wrote: are you going to be selling these or is this a 1 off for your car.

on this board. Lets wait until he has completed his installation and fully tested

the concept.

The parts are not cheap and have to be machined by a local machine shop.

If I got five or more orders I would consider it.

The end user will have some welding and cutting to do. -

mod_mastazMember

mod_mastazMember- 44

Gary, those bolts and plates aren't too expensive to machine out as there are hex stock available which machine shops can use to create bolts. I got a VERY low quote on those bolts because I know of a friend's father who does machine work. A few Socal Club-S12 members, including myself, are trying to replicate this kit based on your designs, BUT there has been a lot of conflicts as to how they can better the design, make it bolt in, or create an entirely better kit. Long story short, creating these kits would be VERY cheap IF we put the machining order together aside from the conflicts. I don't know if making an interest thread would help or if I just need to wait until everyone can agree on this current design. PM me if you want more details on my machining quotes and info. -

1artworkzSenior Member

1artworkzSenior Member- 1143

If someone else wants to make the parts, that's great. I have no real interest in supplying them.

It would be interesting to see the other ideas. I paid more than $150 for all the parts for one

complete set. It would be great if someone can do it cheaper and with a simpler design. -

1artworkzSenior Member

1artworkzSenior Member- 1143

-

jn1czSenior Member

jn1czSenior Member- 1520

Would it be asking too much for a mod or the author to make a separate thread w/o all the extraneous posts and input or has this already been done? There are 8 pages (so far) to wade through here.

*******

edit: Okay…I'm a fuktard…the link to the page was so big I missed it ops:

ops:

-

85z31t88Senior Member

85z31t88Senior Member- 867

Looks simply amazing. It should have come like this from the factory.

What are the nuts for on the arm itself by the poly bushings? Some type of adjustment?'85 300zx turbo: exhaust, intercooler, coilovers, etc…SOLD, will be missed

'86 300zx turbo: starting over

'97 Dodge 2500: 12v Cummins …selling and will be missed

'94 Jeep Cherokee: D60 Front 14b rear, both locked and 5.38 gears, 37" mtr's

2015 Ram 2500 megacab laramie cummins black appearance package -

1artworkzSenior Member

1artworkzSenior Member- 1143

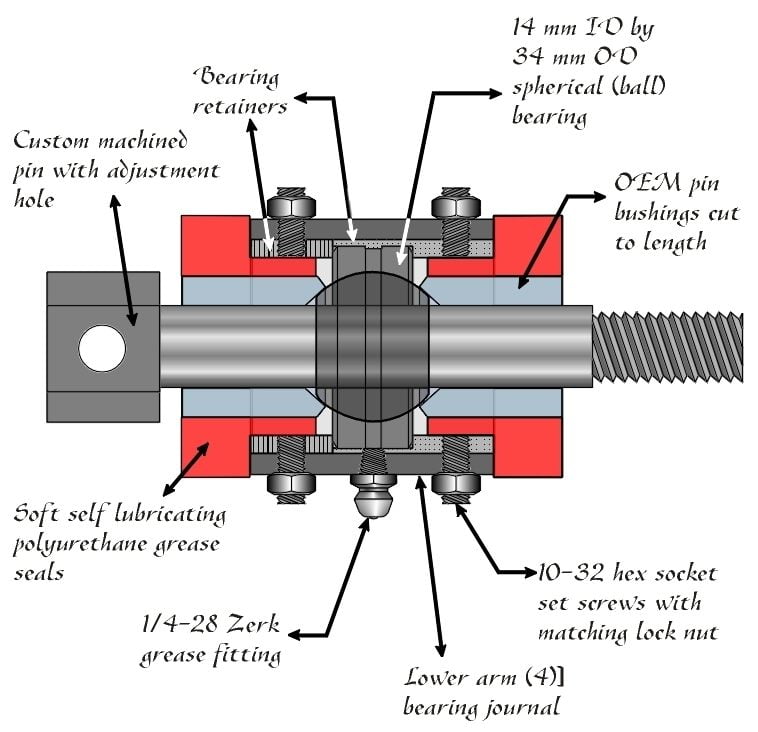

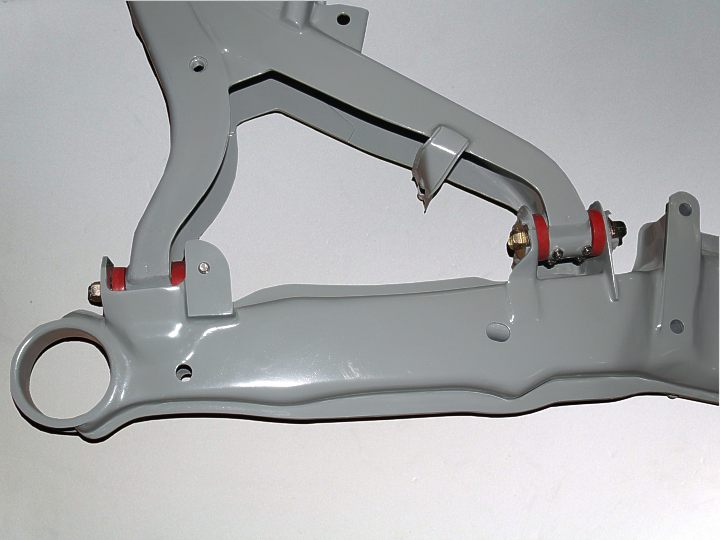

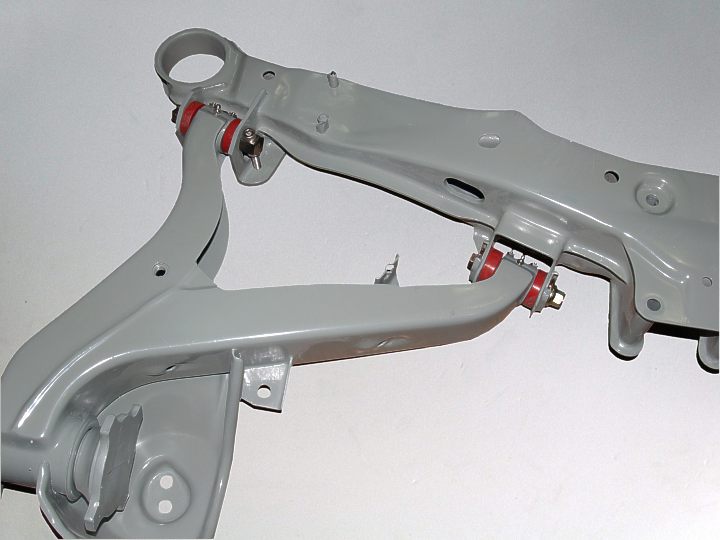

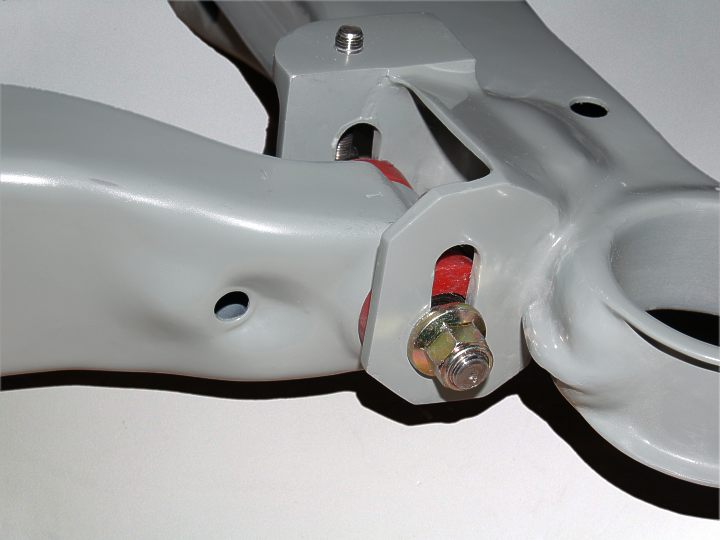

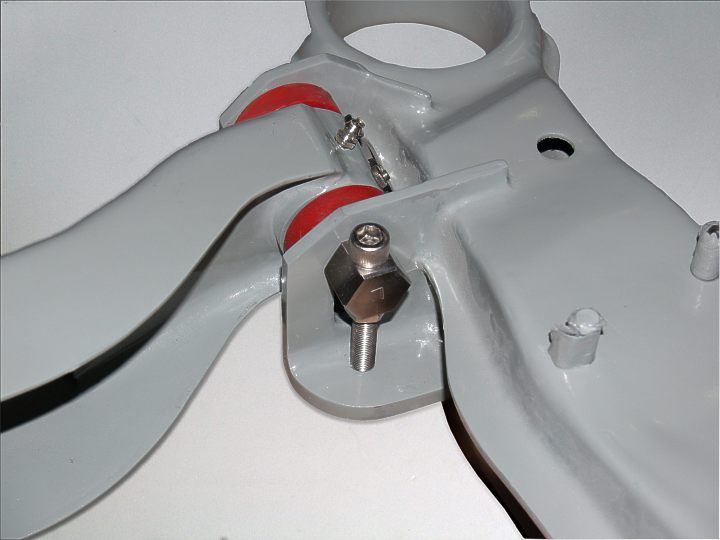

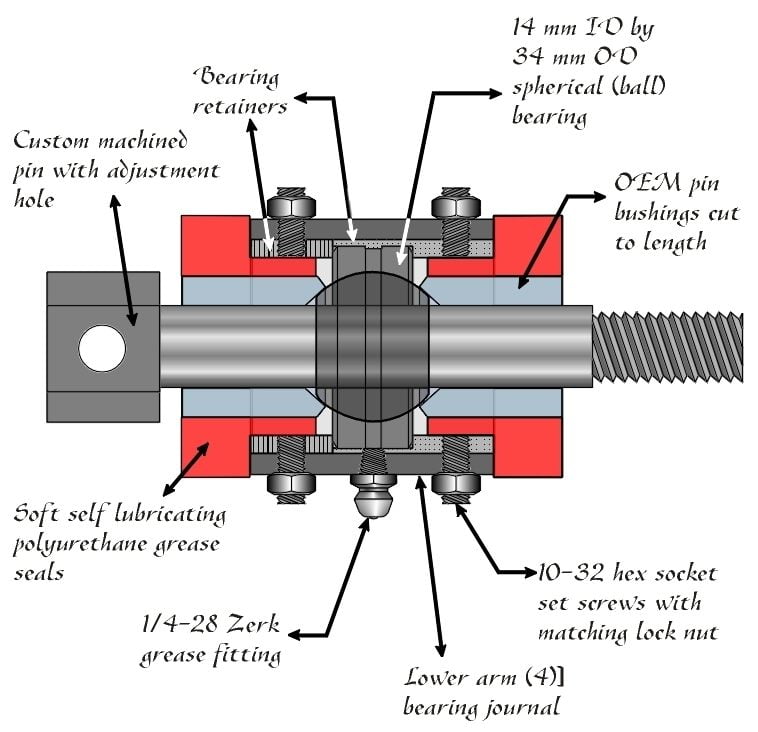

Hopefully this drawing will clarify the individual parts.85z31t88 wrote: What are the nuts for on the arm itself by the poly bushings? Some type of adjustment?

The 10-32 hex socket set screws with matching lock nut are to keep the lower arm bearing journals from

sliding back and forth on bearing retainers. The soft self lubricating polyurethane grease seals are too

soft to prevent movement of the lower arm. They are only there to keep water and dirt out and grease

in.

There are five set screws per journals. Two for each set of bearing retainers (2retainers/bearing) and

one for the spherical bearing. Although the drawing shows the set screws opposite each other, in reality

they are about 30ð apart when measured from the center of the pin.

There is one Zerk grease fitting per bearing.

-

DeleriousZSenior Member

DeleriousZSenior Member- 6874

nom nom nom.

what kind of grease would be used in this setup? not the poly grease i'd assume…

any idea on timeframe of this? i'm getting antsy to put my subframe back together!

1988 300zxt. gt35, stance, etc. Wheels: Varrstoen ES2 18x9.5 et-13 225/40. 18x10.5 et0 245/40

1990 jetta vr6'd -

1artworkzSenior Member

1artworkzSenior Member- 1143

I'm not really interested in doing this on a one order at a time. I have a local machine shop doDeleriousZ wrote:

What kind of grease would be used in this setup? not the poly grease I'd assume…

Lubrimatic/Stant/Truflate 11404 Marine Wheel Bearing Grease

Any idea on time frame of this? I'm getting antsy to put my subframe back together!

the work and it would be cheaper if there was a group buy. A group buy of five or more would

be the least I would consider at a time.

CAUTION: If you are interested in this project, you should know: If you don't have the

tools and expertise you will have to have someone qualified do the work for you. It is time

consuming and requires precise measuring. It is expensive. AND I disavow any and all responsibility

for the presumed benefits, workability, safety, accident or death as a result of buying and installing

these parts on a car.

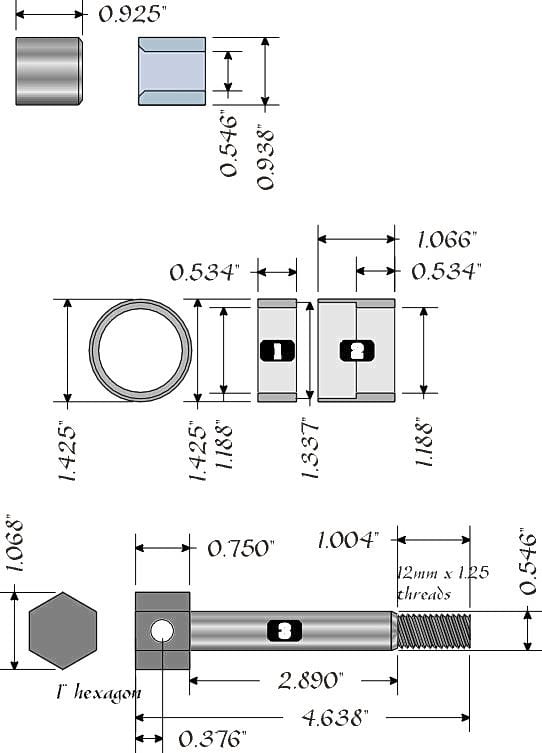

In the next week I will post a total price for the parts I will supply as shown in the first 5 pictures

below. You will have to buy the McMaster-Carr spherical bearings on your own.

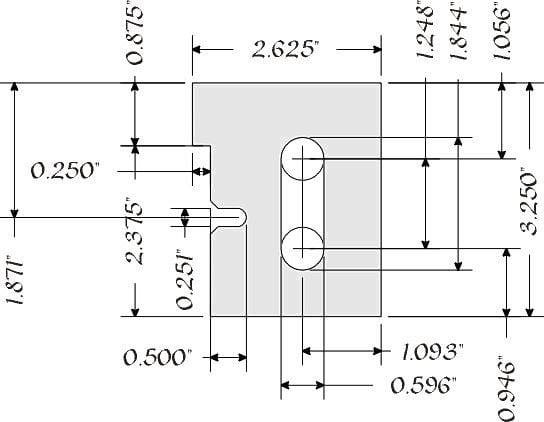

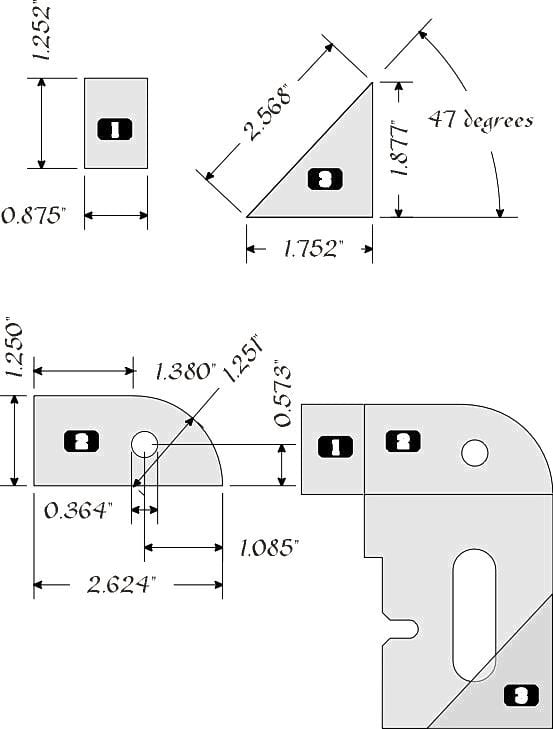

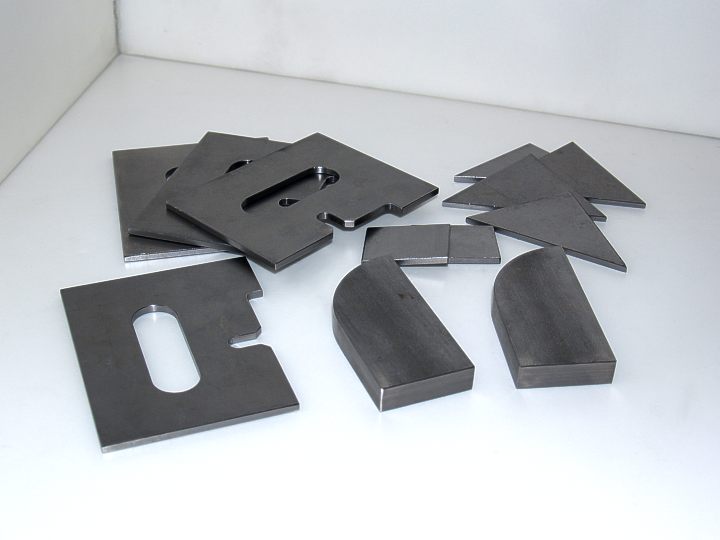

One set of adjuster plates that will need to be welded together and to the subframe

Bearing retainer sleeves

These are the pins that attach the lower arms to the subframe. They can be supplied

color treated for a bit more rust resistance or plain. I am having mine chrome plated

Fasteners & Zerk fittings, either in SS or plain, plus tap and drills

Special soft self lubricating grease seals

Complete set of instruction with photograph

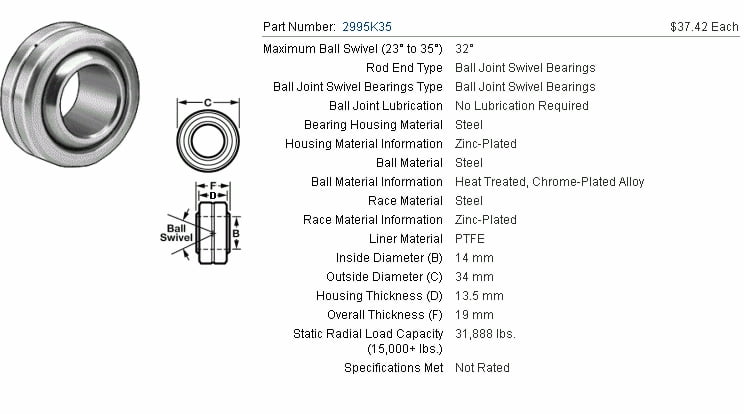

You will have to buy these on your own. http://www.mcmaster.com

-

1artworkzSenior Member

1artworkzSenior Member- 1143

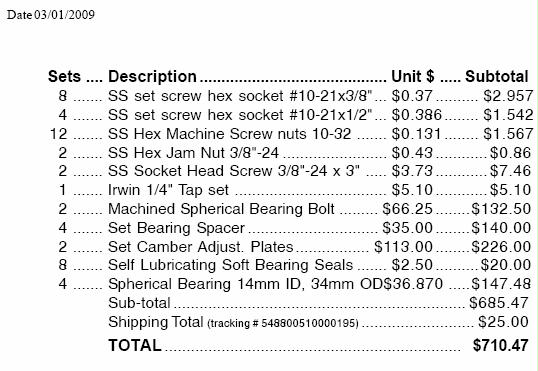

Here is the break down on the parts costs. These are the actual costs

I paid except for the shipping. Just the total costs for the machined parts are

$498.50. My guess is that this is way beyond the reasonable for most people.

-

adamvann3Senior Member

adamvann3Senior Member- 4160

Good write up on everything. I am hoping some will benefit. You have this installed or know is someone has this installed yet to test it out?86na - BlueZ

Shiro #366 - Kouki Monster

85t - Mr Tickles -

1artworkzSenior Member

1artworkzSenior Member- 1143

Myself an CAG8OR went in together on the parts. He maybe starting his conversion this

coming week end. Mine is done. The suspension will be installed this summer but the

car won't be road worthy for another couple years.

CAG8OR should know before then. -

CAG8ORSenior Member

CAG8ORSenior Member- 171

I will try my best to get this started this weekend, however no guarantees on that. I will take plenty of pictures along the way and keep everyone posted. I am sure this will take me a week or so to complete as I have to send out the rear cross member for welding. I don't have my welder any more. I then have to get it prepped and powder coated before re-installation. I have been waiting for this for soo long now, what is another couple weeks or so. Many thanks to Gary for completing this project! With any luck this will function as good as it looks!2006 & 2007 Basketball National Champions! 2005, 6, & 7 Basketball SEC Champions! 2006 Football National Champions! 2006 Football SEC Champions! 2008 SEC Champions! 2008 Football National Champions! First University in history to capture three titles in a single year! I was there at all of them, and it was awesome! Go Gators! -

1artworkzSenior Member

1artworkzSenior Member- 1143

OK. So here it is. The PDF below tells how I did it and the picture in this post

give an overview of the results and parts required. I had a local (CA) machine

shop make the parts for me. The cost was a little under $500.00.

I don't offer these for sale. This was a 'one-off' project.

If you choose to do this and want the "Self Lubricating Soft Bearing Poly Seals,"

I will sell the set for $30.00.

http://www.garymolitor.com/300zx/camber … mounts.pdf